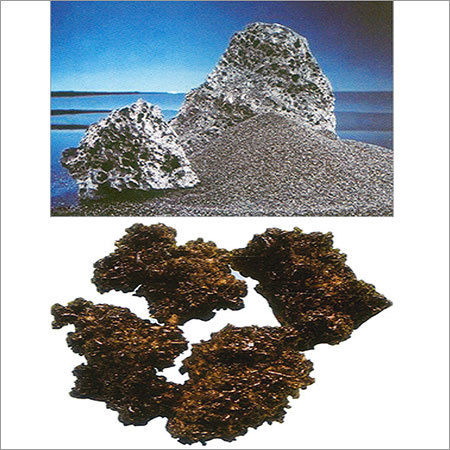

Brown Fused Alumina

Brown Fused Alumina Specification

- Chemical Composition

- Al2O3 95% min, SiO2 1.5% max, Fe2O3 0.4% max, TiO2 3% max

- Application

- Abrasives, refractory materials, blasting, grinding, surface preparation

- Form

- Grits, powder, and lumps

- Density

- 4.10 Gram per cubic centimeter(g/cm3)

- Melting Point

- Approximately 2050C

- Water Absorption

- Negligible

- Usage & Applications

- Used in abrasive tools, sandblasting, refractory linings, non-slip flooring, wear-resistant surfaces

- Hardness (%)

- Mohs hardness: 9

- Surface Finish

- Rough or angular, depending on grading

- Purity(%)

- 95% min (Al2O3)

- Product Type

- Industrial abrasive and refractory grain

- Types of Refractories

- Basic Refractory

- Shape

- Granular, angular

- Porosity

- Low

- Dimensional Stability

- Excellent at high temperatures

- Strength

- High crushing strength, suitable for heavy-duty industrial use

- Specific Gravity

- 3.9 g/cm

- Thermal Conductivity

- Good thermal conductivity

- Color

- Brown

About Brown Fused Alumina

Having quality oriented approach, we are able to offer the best grade Brown Fused Alumina. This product is produced by smelting quality-assured calcined bauxite with the aid of our modern electric arc furnaces. Finds wide applications in blasting and surface hardening, provided product is widely demanded for grinding metals of high tensile strength. Available in various packaging options, provided Brown Fused Alumina can be bought from us at economical prices.

Key Points:

- High strength

- Suitable for manufacturing refractory products

- Sharp abrasive in nature

- Safe to use

Process of Production

Brown Fused Alumina is produced by the smelting of Calcined Bauxite in an electric arc furnace at temperatures greater than 2000oC. A slow solidification process follows the fusion, to yield blocky crystals. The melting help in removing residual sulphur and carbon, Strict control over Titania levels during the fusion process ensures optimum toughness of the grains.

Then the cooled crude is further crushed, cleaned of magnetic impurities in high intensity magnetic separators and classified into narrow size fractions to suit the end use. Dedicated lines produce products for different applications.

Application :

Brown Fused Alumina is a tough, sharp abrasives which is highly suitable for grinding metals of high tensile strength. Its thermal properties make it an excellent material for use in the manufacture of refractory products. This material is also used in other applications like blasting and surface hardening.

Technical Specification :

| Grade | Specification | Chemical Composition | ||||

| AI2O3 | SiO2 | Fe2O3 | TiO2 | CaO | ||

| Brick Grade | 0-1,1-3,3-5mm -8+16,-16+30,-30+60 mesh, Fines | > 95.2 | < 1.0 | < 0.3 | < 0.3 | < 0.4 |

| Castable Grade | 0-1,1-3,3-5mm -8+16,-16+30,-30+60 mesh, Fines | > 95 | < 1.5 | < 0.3 | < 0.3 | < 0.4 |

| Vitrified Grade | F12-F220 | > 95.5 | < 1.0 | < 0.3 | 2.2-3.0 | < 0.4 |

| Resin & Blasting Grade | F12-F220 | > 95 | < 1.5 | < 0.3 | < 0.3 | < 0.4 |

| Micro Grade | P240-P1200 | > 92-95 | < 1.0-1.8 | < 0.3-0.5 | < 2.2-45 | |

| F240-F1000 | > 88-95 | < 1.0-2.5 | < 0.3-0.5 | < 2.2-6.5 | | |

| Melting Point | 2050oC | |||||

| Refractoriness | 1980oC | |||||

| True Density | 3.90 ming/cm3 | |||||

| Mohs Hardness | 9.00min | |||||

Brick / Vitrified Grade BFA : Is produced using special grade Bauxite in controlled fusion parameters. This grade is suitable for Bricks / Vitrified products preventing Cracks/Fissures, Holes and Black spots in the end product.

Versatile Industrial Applications

Brown Fused Aluminas high hardness (Mohs 9) and exceptional strength make it indispensable in abrasive tool manufacturing, sandblasting, grinding, refractory linings, non-slip flooring, and wear-resistant surfaces. Its thermal and dimensional stability ensures reliable performance in demanding environments, supporting a variety of industrial processes across India and beyond.

Exceptional Physical and Chemical Properties

This material combines a high alumina content (minimum 95%) with minimal impurities such as SiO2 (<1%) and Fe2O3 (0.4% max), resulting in outstanding durability, low porosity, and high thermal conductivity. Its bulk density ranges from 1.6 to 2.1 g/cm, and it maintains integrity at melting points up to 2050C, making it suitable for basic refractory applications.

Flexible Grain Sizing and Packaging

Clients can select from standard grain sizes (F8F220, P12P220) or request custom options to suit specific requirements. Packaging is available in 25 kg bags, 1MT jumbo bags, and bespoke formats, ensuring convenient handling and storage for any industrial-scale operation.

FAQs of Brown Fused Alumina:

Q: How is Brown Fused Alumina used in abrasive and refractory applications?

A: Brown Fused Alumina is incorporated into abrasive tools for grinding and cutting, as well as in sandblasting for surface preparation. Its superior hardness and thermal stability also make it an ideal aggregate in refractory linings, offering lasting performance at high temperatures and under mechanical stress.Q: What are the main benefits of choosing Brown Fused Alumina for industrial use?

A: Key benefits include high alumina purity (95%), excellent crushing strength, negligible water absorption, and low magnetic and silica content. These properties deliver reliable abrasion performance, durability under repeated usage, and chemical stability during high-temperature processes.Q: When should I select specific grain sizes or custom sizing?

A: Grain size selection depends on the end-use: coarser sizes (F8F46) suit heavy-duty grinding, while finer sizes (F240 and beyond) are appropriate for precision finishing. Custom grits are available upon request, catering to unique requirements in abrasives or refractory manufacturing.Q: Where is Brown Fused Alumina sourced or supplied from in India?

A: Brown Fused Alumina is supplied, exported, and imported by leading industrial materials companies across India. It is readily available for delivery nationwide, with tailored logistics and packaging solutions to support diverse customer needs.Q: What is the process for manufacturing Brown Fused Alumina?

A: Brown Fused Alumina is produced by electro-fusing bauxite at about 2050C, resulting in an angular granular material of high alumina content. The product is then crushed, graded into specified grain sizes, and optionally customized to customer requirements before packaging.Q: How should Brown Fused Alumina be stored and handled to maintain quality?

A: It should be stored in a dry, clean environment using the provided sealed 25 kg bags or 1MT jumbo bags to avoid moisture absorption and contamination. Proper storage ensures the material retains its abrasive properties and chemical composition.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Refractory Minerals Category

Ferrosilicon Nitride

Product Type : Other, Ferrosilicon Nitride

Application : Widely used as a refractory material with high strength and thermal stability, mainly in blast furnace tap hole areas and iron troughs

Chemical Composition : Si3N4, Fe, Si, N

Specific Gravity : 2.62.8

Thermal Conductivity : Low

Porosity : Low apparent porosity (< 25%)

Fused Zirconia Mullite

Product Type : Other, Fused Zirconia Mullite

Application : Refractory lining, kiln furniture, glass furnace, metallurgy, ceramics

Chemical Composition : ZrO: 3335%, AlO: 4546%, SiO: 1820%

Specific Gravity : 3.23.4 g/cm

Thermal Conductivity : Low thermal conductivity

Porosity : Low

Fused Spinel Stone

Product Type : Other, Fused Spinel Stone

Application : Refractory linings, steelmaking, cement rotary kilns, glass furnaces

Chemical Composition : MgOAl2O3 (Magnesium Aluminium Oxide)

Specific Gravity : 3.55 g/cm 3.6 g/cm

Thermal Conductivity : Low

Porosity : Low apparent porosity

Boron Carbide

Product Type : Other, Boron Carbide

Application : Industrial abrasives, nuclear reactors, armor, nozzles, refractories

Chemical Composition : Boron 7778%, Carbon 2122%

Specific Gravity : 2.52

Thermal Conductivity : 29 W/(mK)

Porosity : Low

GST : 33AZHPS1057K1Z6

|

|

CERAMICS INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry