White Fused Alumina Variants

White Fused Alumina Variants Specification

- Hardness (%)

- Mohs hardness 9

- Water Absorption

- Negligible, virtually zero

- Chemical Composition

- Al2O3 99.25%, SiO2 0.10%, Fe2O3 0.10%, Na2O 0.30%

- Surface Finish

- Superior, ideal for precise polishing operations

- Melting Point

- Approximately 2050C (3722F)

- Usage & Applications

- Precision casting, ceramic, abrasive blasting, coated and bonded abrasives

- Form

- Grits, grains, fines, micro powder

- Density

- 4.00 Gram per cubic centimeter(g/cm3)

- Application

- Abrasive blasting, refractory materials, surface treatment, grinding, polishing, and lapping of hard materials

- Purity(%)

- 99.25%

- Product Type

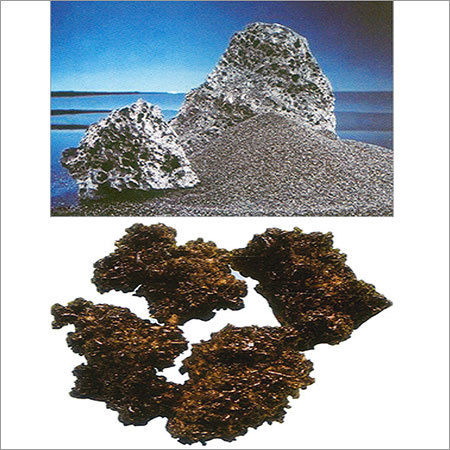

- White Fused Alumina Variants

- Types of Refractories

- High alumina refractory, castable, corrosion-resistant refractory

- Shape

- Angular, sharp-edged grains and powders

- Porosity

- Low porosity, dense structure

- Dimensional Stability

- Excellent at high temperatures

- Strength

- High mechanical strength, excellent toughness

- Specific Gravity

- 3.90 g/cm

- Thermal Conductivity

- Low, provides good thermal insulation properties

- Color

- Pure white

About White Fused Alumina Variants

| Products / Spec | AI2O3 | SiO2 | Fe2O3 | Na2O |

| WFA Low Soda Grains and fines | >99.2 | <0.2 | <0.1 | <0.2 |

| WFA 98 Grains and fines | >98 | <0.2 | <0.2 | <0.5 |

| WFA 98% Demagnetized Fines -200,-325 and -500Mesh | >98 | <0.2 | <0.5 | <0.8 |

Application :

WFA Low soda grains : These grades of WFA has extremely low Na2O levels, Lower than 0.20%. This increases the refractoriness significantly and can be used in refractory applications where high refractorines is required.

WFA 98 Grains : Is a very cost effective WFA Grains produced from a pot furnace. It can be used extensively in castables.

WFA 98% Demagnetised Fines in -200 and -325 mesh is a an extremely cost effective product which can be used in Refractory shapes as well as castables.

Superior Abrasive Properties

White Fused Alumina is engineered for consistent abrasive performance, offering medium friability for efficient abrasive reuse. Its extremely high Mohs hardness and sharp grains guarantee precise cutting, grinding, and polishing on hard surfaces, while controlled trace magnetic substances ensure purity for critical applications.

Reliability in High-Temperature Operations

With a melting point of approximately 2050C and excellent dimensional stability, White Fused Alumina is ideal for refractory materials in high-heat environments. Its low thermal expansion coefficient and low porosity enhance durability, making it perfect for high alumina, castable, and corrosion-resistant refractories.

Versatile Applications and Quality Packaging

Available in multiple particle sizes and forms, White Fused Alumina suits a wide array of tasksfrom abrasive blasting to precision casting. Delivered in robust 25 kg or 1000 kg packaging, it remains stable and effective, even after long-term storage under proper conditions.

FAQs of White Fused Alumina Variants:

Q: How is White Fused Alumina used in abrasive blasting and surface treatment?

A: White Fused Alumina is applied in abrasive blasting and surface treatment for its sharp-edged grains and superior toughness, rapidly removing contaminants and producing a clean, smooth surface. Its high purity and consistent grain size ensure efficient, reusable abrasives and minimal residue.Q: What are the primary benefits of using White Fused Alumina in refractory materials?

A: The key advantages include excellent dimensional stability at high temperatures, low thermal conductivity, and high mechanical strength. These properties make White Fused Alumina ideal for high alumina refractories, castables, and corrosion-resistant applications, ensuring longevity and durability.Q: When should I opt for customized grain size variants of White Fused Alumina?

A: Customized grain sizes are recommended when specific surface profiles or polishing requirements are needed, or when matching unique application standards is critical. Selecting the appropriate grain size improves process efficiency and achieves optimal results for your intended usage.Q: Where can White Fused Alumina variants be stored for indefinite shelf life?

A: White Fused Alumina should be stored in a clean, dry environment, away from moisture and contaminants. Properly packaged in 25 kg bags or 1000 kg jumbo bags, it maintains stability and performance indefinitely if protected from extreme conditions.Q: What is the process for abrasive reuse with medium friability White Fused Alumina?

A: White Fused Alumina, with medium friability, can be reused multiple times in abrasive blasting processes. After each cycle, the material retains its sharp edges, although some grains may fracture and lose effectiveness, making it necessary to refresh the abrasive periodically.Q: How does the low water absorption property benefit usage in precision casting and ceramics?

A: Negligible water absorption prevents unwanted moisture transfer, reducing the risk of defects in casting or ceramic items. This dense, virtually non-porous structure ensures dimensional accuracy and surface quality during manufacture.Q: Why is white fused alumina favored for polishing hard materials?

A: Its angular grains, high purity, and Mohs hardness of 9 enable precise and effective polishing of hard surfaces. The superior surface finish achieved minimizes scratches, meeting stringent requirements for advanced grinding, lapping, and finishing applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Refractory Minerals Category

Ferrosilicon Nitride

Density : 2.5 Gram per cubic centimeter(g/cm3)

Purity(%) : > 98%

Application : Widely used as a refractory material with high strength and thermal stability, mainly in blast furnace tap hole areas and iron troughs

Color : Gray to dark gray

Form : Powder/Granule

Usage & Applications : Production of refractory bricks, tap hole clay, blast furnace lining, metallurgy, ceramics industry

Fused Zirconia Mullite

Density : 3.1 Gram per cubic centimeter(g/cm3)

Purity(%) : 99%

Application : Refractory lining, kiln furniture, glass furnace, metallurgy, ceramics

Color : White to offwhite

Form : Solid (Block, brick, granular, powder)

Usage & Applications : Steel, glass, ceramics, cement, and petrochemical industries as insulating refractory material

Fused Spinel Stone

Density : 3.6 Gram per cubic centimeter(g/cm3)

Purity(%) : >98%

Application : Refractory linings, steelmaking, cement rotary kilns, glass furnaces

Color : Blue or light purple

Form : Solid stone/block

Usage & Applications : Ideal for critical hightemperature zones in kilns and furnaces

Boron Carbide

Density : 2.52 Gram per cubic centimeter(g/cm3)

Purity(%) : above 99%

Application : Industrial abrasives, nuclear reactors, armor, nozzles, refractories

Color : Black / Gray

Form : Powder, granules, blocks

Usage & Applications : Used in abrasives, armor plating, neutron absorption, blasting nozzles

GST : 33AZHPS1057K1Z6

|

|

CERAMICS INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry