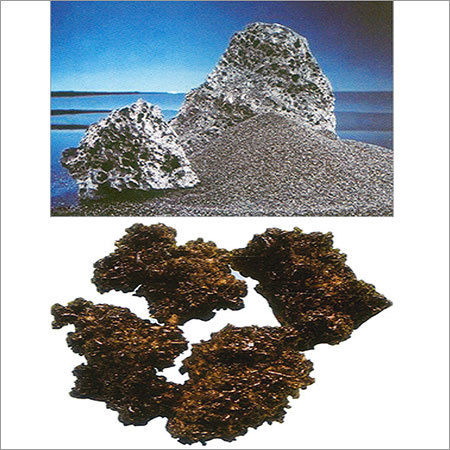

Boron Carbide

Boron Carbide Specification

- Melting Point

- 2450C

- Surface Finish

- Smooth

- Form

- Powder, granules, blocks

- Purity(%)

- above 99%

- Hardness (%)

- Mohs hardness: 9.3

- Water Absorption

- Negligible

- Usage & Applications

- Used in abrasives, armor plating, neutron absorption, blasting nozzles

- Chemical Composition

- Boron 77-78%, Carbon 21-22%

- Density

- 2.52 Gram per cubic centimeter(g/cm3)

- Application

- Industrial abrasives, nuclear reactors, armor, nozzles, refractories

- Product Type

- Boron Carbide

- Types of Refractories

- Acidic Refractory

- Shape

- Powder, granules, block

- Porosity

- Low

- Dimensional Stability

- Excellent

- Strength

- High mechanical strength

- Specific Gravity

- 2.52

- Thermal Conductivity

- 29 W/(mK)

- Color

- Black / Gray

About Boron Carbide

Process of Production :

Boron Carbide is smelted from boric acid and powdered carbon in electric furnace under high temperature. It is one of the hardest man-made materials available in commercial quantities that has a finite melting point low enough to permit its relatively easy fabrication into shapes. Some of Boron Carbide's unique properties include: high hardness, chemical inertness, and a high neutron absorbing, cross section.

Applications :

- Boron Carbide is well suited to a variety of industrial applications including:

- Abrasives for lapping and ultrasonic cutting, Anti-Oxidant in carbon-bonded refractory mixes, Armor Nuclear applications such as reactor control rods and neutron absorbing shielding.

- Wear parts such as blasting nozzles, wire-drawing dies, powdered metal and ceramic forming dies, thread guides.

- It is used as an additive in continuous casting refractories due to its high metling point and thermal stability.

Specification :

| BRANDS | B (%) | C(%) | Fe2O3 (%) | Si (%) | B4C(%) |

| F60-F150 | 77-80 | 17-19 | 0.25-0.45 | 0.2-0.4 | 96-98 |

| F180-F240 | 76-79 | 17-19 | 0.25-0.45 | 0.2-0.4 | 95-97 |

| F280-F400 | 75-79 | 17-20 | 0.3-0.6 | 0.3-0.8 | 93-97 |

| F500-F800 | 74-78 | 17-20 | 0.4-0.8 | 0.4-1.0 | 90-94 |

| F1000-F1200 | 73-77 | 17-20 | 0.5-1.0 | 0.4-1.2 | 89-92 |

| 60-150mesh | 76-80 | 18-21 | 0.3max | 0.5max | 95-98 |

| -100mesh | 75-79 | 17-22 | 0.3max | 0.5max | 94-97 |

| -200mesh | 74-79 | 17-22 | 0.3max | 0.5max | 94-97 |

| -325mesh | 73-78 | 19-22 | 0.5max | 0.5max | 93-97 |

| -25micron | 73-78 | 19-22 | 0.5max | 0.5max | 91-95 |

| -10micron | 72-76 | 18-21 | 0.5max | 0.5max | 90-92 |

Versatility Across Key Industries

Boron Carbides adaptability allows it to serve multiple sectors effectively. Its unique blend of high hardness, thermal stability, and chemical inertness makes it valuable in the manufacture of industrial abrasives, protective armor, nuclear reactor components, and high-performance nozzles. Its dimensional and structural stability ensures reliability even under extreme conditions.

Tailored Particle Sizes and Consistent Quality

To match diverse manufacturing and application demands, Boron Carbide is offered in fused 100 mesh, 200 mesh, and customizable grain sizes. Consistency in chemical composition (Boron 77-78%, Carbon 21-22%) and options for ISO-certified supply ensure confidence in quality, whether for bulk industrial use or specialized requirements.

Safe Handling and Sustainable Storage Solutions

Boron Carbide is non-flammable, non-toxic, and stable under recommended storage conditions. Standard packaging in robust HDPE bags and drums ensures safe, contamination-free delivery and storage. While it poses negligible water absorption and is not hazardous, its advised to use a mask to avoid inhalation of fine particles during handling.

FAQs of Boron Carbide:

Q: How is Boron Carbide typically used in industrial applications?

A: Boron Carbide is employed in sectors requiring extreme hardness and durability, such as abrasives manufacturing for grinding and lapping, as armor plating for ballistic protection, as a neutron absorber in nuclear reactors, and for making blast nozzles and refractory materials.Q: What customization options are available for Boron Carbides grain size and particle distribution?

A: The material is available in standard fused 100 mesh, 200 mesh, and can be tailored to specific grain size and particle distribution requirements as per client specifications, ensuring optimal performance in various end-use scenarios.Q: When should Boron Carbide be handled with protective equipment?

A: It is recommended to wear a mask during handling of powders or fine granules to avoid inhalation of airborne particles, despite the product being non-toxic and non-flammable. Such precautions help maintain workplace safety.Q: Where is Boron Carbide most commonly sourced and supplied?

A: Boron Carbide is produced, exported, and supplied widely from India, serving both domestic and global markets for industries like defense, energy, manufacturing, and materials processing.Q: What are the benefits of using Boron Carbide for armor and neutron absorption applications?

A: Owing to its high mechanical strength, excellent dimensional stability, and low density, Boron Carbide provides outstanding protection in armor systems and efficient neutron absorption in nuclear reactors, contributing to both safety and performance.Q: How does Boron Carbide maintain its properties over time during storage?

A: When stored under recommended dry and sealed conditions, Boron Carbide remains stable with a long shelf life. Its low porosity and negligible water absorption prevent degradation and ensure it retains purity until use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Refractory Minerals Category

White Fused Alumina

Application : Abrasive blasting, grinding, polishing, refractory, surface treatment, and lapping

Color : White

Chemical Composition : Al2O3: 99% min

Types of Refractories : Other, Refractory bricks, castables, and shaped products

Dimensional Stability : Other, Excellent at high temperatures

Porosity : Very low

Ferrosilicon Nitride

Application : Widely used as a refractory material with high strength and thermal stability, mainly in blast furnace tap hole areas and iron troughs

Color : Gray to dark gray

Chemical Composition : Si3N4, Fe, Si, N

Types of Refractories : Other, Nitride bonded refractories

Dimensional Stability : Other, Excellent stability at high temperatures

Porosity : Low apparent porosity (< 25%)

White Fused Alumina Variants

Application : Abrasive blasting, refractory materials, surface treatment, grinding, polishing, and lapping of hard materials

Color : Pure white

Chemical Composition : Al2O3 99.25%, SiO2 0.10%, Fe2O3 0.10%, Na2O 0.30%

Types of Refractories : Other, High alumina refractory, castable, corrosionresistant refractory

Dimensional Stability : Other, Excellent at high temperatures

Porosity : Low porosity, dense structure

Crushed Ceramic Grains

Application : Abrasive blasting, surface preparation, antiskid flooring, refractory lining, filtration media

Color : Light brown to offwhite

Chemical Composition : Al2O3: 6070%, SiO2: 2030%, Others: <10%

Types of Refractories : Other, Synthetic, ceramicbased refractories

Dimensional Stability : Other, Good dimensional stability at high temperature

Porosity : Low to medium porosity

GST : 33AZHPS1057K1Z6

|

|

CERAMICS INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry