White Fused Alumina

White Fused Alumina Specification

- Melting Point

- Over 2000C

- Form

- Grain, powder, or customized sizes

- Water Absorption

- Negligible

- Density

- 3.6 Gram per cubic centimeter(g/cm3)

- Purity(%)

- 99% min

- Surface Finish

- Smooth, grit-dependent

- Application

- Abrasive blasting, grinding, polishing, refractory, surface treatment, and lapping

- Chemical Composition

- Al2O3: 99% min

- Hardness (%)

- 9 Mohs scale (approximately 99% of corundum hardness)

- Usage & Applications

- Suitable for abrasives, refractories, surface preparation, and precision casting

- Product Type

- White fused alumina grain or powder

- Types of Refractories

- Refractory bricks, castables, and shaped products

- Shape

- Angular

- Porosity

- Very low

- Dimensional Stability

- Excellent at high temperatures

- Strength

- High mechanical strength

- Specific Gravity

- 3.90 g/cm

- Thermal Conductivity

- High

- Color

- White

- Moisture Content

- 0.3%

- Refractoriness Under Load (RUL)

- >1700C

- Toxicity

- Non-toxic and environmentally safe

- Friability

- Low, allows for long abrasive life

- Grain Sizes Available

- F4F220 (as per FEPA standards)

- Bulk Density

- 1.551.95 g/cm, grain size dependent

- Thermal Expansion Coefficient

- 8.1 x 10/K at 201000C

- Packaging

- 25 kg or 50 kg bags, jumbo bags, or customized packaging

- Shelf Life

- Indefinite under proper storage conditions

- Electrical Resistivity

- High

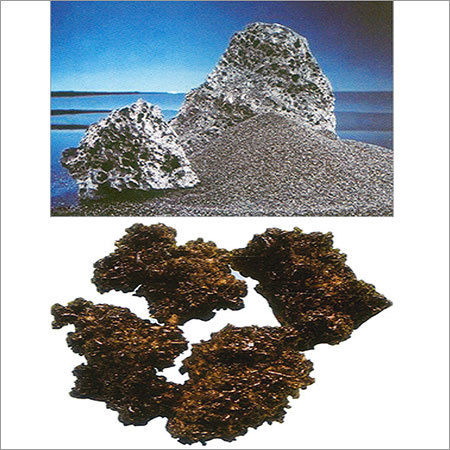

About White Fused Alumina

White Fused Alumina

Raw Material and Process of Production

- White Fused Alumina is a high purity, synthetic mineral.

- It is manufactured by the fusion of controlled quality pure grade Bayer Alumina in an electric arc furnace at temperatures greater than 2000C followed by a slow solidification process.

- Strict control over quality of raw materials and fusion parameters ensure products of high purity and high whiteness.

- The cooled crude is further crushed, cleaned of magnetic impurities in high intensity magnetic separators and classified into narrow size fractions to suit the end use.

Application :

Dedicated lines produce products for different applications.

White Fused Alumina is highly friable and hence used in Vitrified Bonded Abrasives products where cool, fast cutting action is essential and also in the manufacture of high purity alumina refractories. Other applications include use in Coated Abrasives, Surface treatment, Ceramic Tiles, Anti-skid Paints, Fluidized Bed Furnaces and Skin / Dental Care.

Technical Specification :

| Items | Unit | Index | Typical | ||

| Chemical composition | AI2O3 | % | 99.00 min | 99.52 | |

| SiO2 | % | 0.20 max | 0.11 | ||

| Fe2O3 | % | 0.10 max | 0.07 | ||

| Na2O | % | 0.40 max | 0.27 | ||

| Refractoriness | OC | 1850 min | |||

| Bulk Density | g/cm3 | 3.50 min | |||

| Mohs Hardness | ---- | 9.00 min | |||

| Principal Crystalline Phase | --- | AI2O3 | |||

| Refractory Grade | Grain | mm | 0-50,0-1,1-3,3-5,5-8 | ||

| Mesh | -8+16,16+30,-30+60,-60+90 | ||||

| Fines | Mesh | -100,-200,-325 | |||

| Abrasive & Blasting Grade | FEPA | F12-F220 | |||

| Polishing & Grinding Grade | FEPA | F240-F1200 | |||

Superior Abrasive Performance

White Fused Alumina provides low friability and long abrasive life, making it a preferred choice in precision grinding, lapping, and polishing tasks. Its high purity ensures minimal contamination, while the angular grains offer efficient cutting capabilities and a smooth surface finish, which is grit dependent.

Ideal for High-Temperature Applications

This material excels in refractory uses such as bricks, castables, and shaped products due to its high refractoriness under load (>1700C) and outstanding dimensional stability. Its superior thermal conductivity and very low porosity ensure optimal performance even in extreme conditions.

Environmentally Safe and Versatile

Produced with a non-toxic profile and negligible moisture content (0.3%), White Fused Alumina is suitable for sensitive applications, including surface preparation and precision casting. Custom packaging options and indefinite shelf life under proper storage highlight its adaptability for exporters, suppliers, and both small and large-scale operations.

FAQs of White Fused Alumina:

Q: How is White Fused Alumina used in abrasive blasting and grinding processes?

A: White Fused Alumina, with its angular grain shape and high hardness (9 Mohs), provides effective cutting and surface cleaning in abrasive blasting and grinding applications. The low friability ensures the grains retain their shape longer, delivering a consistently smooth finish and extended abrasive life.Q: What grain sizes of White Fused Alumina are available, and how do they affect performance?

A: Grain sizes from F4 to F220, as per FEPA standards, are available. Coarser grains suit heavy-duty cutting and blasting tasks, while finer grades are optimal for polishing and precision lapping, allowing users to select the appropriate grit for specific surface finish requirements.Q: Where can White Fused Alumina be applied in industrial settings?

A: It is widely used in industries such as metalworking, surface preparation, precision casting, and manufacturing refractory bricks and castables. The materials high refractoriness and mechanical strength make it particularly suitable for high-temperature environments.Q: What benefits does White Fused Alumina offer for refractory manufacturing?

A: Due to its high alumina content, superior mechanical strength, high thermal conductivity, and excellent dimensional stability at elevated temperatures, White Fused Alumina enhances the durability, efficiency, and longevity of refractory bricks, shaped products, and castables.Q: How should White Fused Alumina be stored to ensure maximum shelf life?

A: White Fused Alumina has an indefinite shelf life when stored in dry, sealed conditions, away from moisture and contaminants. The low moisture content (0.3%) and non-toxic nature also prevent environmental hazards and product degradation.Q: What packaging options are available for bulk shipments of White Fused Alumina?

A: Packaging options include 25 kg or 50 kg bags, jumbo bags, or customized packages as per customer requirement. These choices ensure safe, convenient transport and storage for exporters, suppliers, and industrial users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Refractory Minerals Category

Brown Fused Alumina

Dimensional Stability : Other, Excellent at high temperatures

Specific Gravity : 3.9 g/cm

Types of Refractories : Basic Refractory

Strength : High crushing strength, suitable for heavyduty industrial use

Thermal Conductivity : Good thermal conductivity

Shape : Other, Granular, angular

Boron Carbide

Dimensional Stability : Other, Excellent

Specific Gravity : 2.52

Types of Refractories : Other, Acidic Refractory

Strength : High mechanical strength

Thermal Conductivity : 29 W/(mK)

Shape : Other, Powder, granules, block

White Fused Alumina Variants

Dimensional Stability : Other, Excellent at high temperatures

Specific Gravity : 3.90 g/cm

Types of Refractories : Other, High alumina refractory, castable, corrosionresistant refractory

Strength : High mechanical strength, excellent toughness

Thermal Conductivity : Low, provides good thermal insulation properties

Shape : Other, Angular, sharpedged grains and powders

Fused Spinel Stone

Dimensional Stability : Other, Excellent at high temperatures

Specific Gravity : 3.55 g/cm 3.6 g/cm

Types of Refractories : Basic Refractory

Strength : High mechanical strength

Thermal Conductivity : Low

Shape : Other, Block/Brick/Stone

GST : 33AZHPS1057K1Z6

|

|

CERAMICS INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry