Fused Alumina Zirconia

Fused Alumina Zirconia Specification

- Hardness (%)

- Mohs 9

- Chemical Composition

- Al2O3 60-70%, ZrO2 25-40%, SiO2 <1.5%, Fe2O3 <0.3%

- Form

- grain, lump, powder

- Usage & Applications

- suitable for bonded abrasives, refractory bricks, coatings

- Density

- 4.2 Gram per cubic centimeter(g/cm3)

- Surface Finish

- angular, rough

- Melting Point

- up to 1900C

- Water Absorption

- very low (<1%)

- Application

- abrasives, refractory castables, blasting, steel & foundry industries

- Purity(%)

- >99%

- Product Type

- synthetic fused refractory raw material

- Types of Refractories

- shaped and unshaped, fused cast

- Shape

- grain, powder, granule

- Porosity

- low

- Dimensional Stability

- excellent at high temperature

- Strength

- high mechanical strength

- Specific Gravity

- 4.2 g/cm

- Thermal Conductivity

- moderate

- Color

- grey to blue

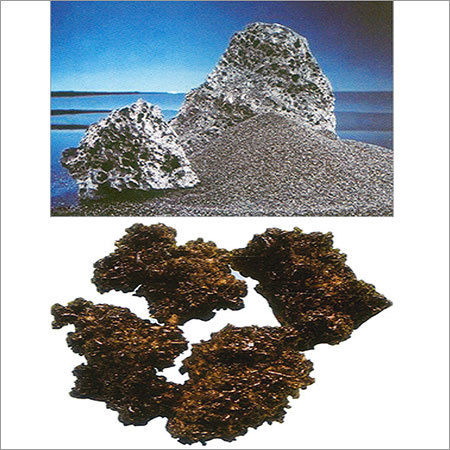

About Fused Alumina Zirconia

Fused Alumina-Zirconia is produced in a high temperature electrical arc furnace by fusing zirconium quartz sand and alumina. It is characterized by hard dense structure, high toughness, good thermal stability. It's suitable for manufacturing large grinding wheels for steel conditioning and foundry snagging, coated tools and stone blasting, etc.

It is also used as an additive in Continuous casting refractories. Due to its high toughness it is used to provide Mechanical strength in these refractories

Technical Specification :

| Brand (Spec) | AZ-25 Index | AZ-25 Typical Value | AZ-40 Index | AZ-40 Typical Value |

| ZrO2 | 23%-27% | 24% | 38%-42% | 39% |

| AI2O3 | 72% min | 74% | 56%-60% | 59% |

| SiO2 | 0.8% max | 0.5% | 0.60% max | 0.4% |

| Fe2O3 | 0.3 % max | 0.2% | 0.3% max | 0.15% |

| TiO2 | 0.8% max | 0.7% | 0.50% max | 0.5% |

| CaO | 0.15% max | 0.14% | 0.15% max | 0.12% |

| True Density (g/cm3) | 4.2 min | 4.23 | 4.6 min | 4.65 |

| Color | Gray or Fresh grey | Gray or Fresh grey | ||

Outstanding High-Temperature Stability

Fused Alumina Zirconia excels in elevated temperatures, maintaining its integrity with refractoriness under load above 1700C and a melting point up to 1900C. Its low thermal expansion and high mechanical strength make it a preferred material for refractory castables and applications where dimensional stability is essential under harsh thermal conditions.

Superior Corrosion and Wear Resistance

Thanks to its unique chemical composition and high purity, this material demonstrates exceptional resistance to slags, molten metals, and corrosive environments. Coupled with a low porosity and water absorption rate under 1%, it serves reliably in abrasive, blasting, and steel industry settings, ensuring longer service life and reduced maintenance.

Versatile Forms for Multiple Applications

Available as grain, powder, granule, or lump, Fused Alumina Zirconia meets diverse needs across industries. Custom grain sizes are possible, making it suitable for bonded abrasives, refractory bricks, and coatings. Its moderate thermal conductivity and rough surface finish further enhance its adaptability and performance in various demanding roles.

FAQs of Fused Alumina Zirconia:

Q: How is Fused Alumina Zirconia typically used in industry?

A: This material is extensively used in bonded abrasives, refractory bricks, castables, coatings, blasting media, and in steel and foundry operations thanks to its high thermal stability, hardness, and corrosion resistance.Q: What are the main benefits of using Fused Alumina Zirconia over conventional alumina?

A: Fused Alumina Zirconia offers superior mechanical strength, greater dimensional stability at high temperatures, and higher resistance to corrosion and slag attack, making it suitable for more demanding environments.Q: When should I choose Fused Alumina Zirconia for my application?

A: Select Fused Alumina Zirconia when your process involves extreme temperatures (above 1700C), exposure to molten metals or corrosive slags, or when high wear resistance and strength are critical for performance.Q: Where can Fused Alumina Zirconia be sourced and in what packaging options?

A: This material is available from specialized exporters, importers, and suppliers in India, and is typically supplied in 25kg or 50kg bags or packaged as per customer requirements for industrial use.Q: What is the manufacturing process for Fused Alumina Zirconia grains?

A: Fused Alumina Zirconia is produced by fusing alumina and zirconia at high temperatures, then cooling and crushing the fused mass into specific grain sizes with low friability and consistent angular shapes.Q: How does the product maintain its performance during storage?

A: Packed in moisture-resistant bags, Fused Alumina Zirconia has a shelf life of 12 months under dry conditions, ensuring it retains low moisture content and excellent quality for industrial processes.Q: What advantages does the angular, rough surface finish provide?

A: The angular and rough surface of Fused Alumina Zirconia grains enhances their cutting ability and anchoring properties, making them highly effective for abrasives and achieving strong bonding in refractory applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Refractory Minerals Category

Ferrosilicon Nitride

Product Type : Other, Ferrosilicon Nitride

Strength : High mechanical strength, especially at high temperatures

Shape : Other, Powder or granule

Porosity : Low apparent porosity (< 25%)

Color : Gray to dark gray

Chemical Composition : Si3N4, Fe, Si, N

Crushed Ceramic Grains

Product Type : Other, Crushed ceramic grains

Strength : High compressive strength

Shape : Other, Angular, irregular crushed particles

Porosity : Low, typically < 5%

Color : Beige to light brown

Chemical Composition : Al2O3, SiO2, minor oxides

Boron Carbide

Product Type : Other, Boron Carbide

Strength : High mechanical strength

Shape : Other, Powder, granules, block

Porosity : Low

Color : Black / Gray

Chemical Composition : Boron 7778%, Carbon 2122%

Fused Zirconia Mullite

Product Type : Other, Fused Zirconia Mullite

Strength : High mechanical strength, resistant to thermal shock

Shape : Other, Block, brick, granular, powder

Porosity : Low

Color : White to offwhite

Chemical Composition : ZrO: 3335%, AlO: 4546%, SiO: 1820%

GST : 33AZHPS1057K1Z6

|

|

CERAMICS INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry