Fused Mullite

Fused Mullite Specification

- Application

- Refractories, kiln furniture, foundry, ceramics, glass industry, metallurgy, and high-temperature insulating materials

- Density

- 3.1 Gram per cubic centimeter(g/cm3)

- Purity(%)

- Typically >98%

- Surface Finish

- Rough as produced, can be processed as required

- Hardness (%)

- Mohs hardness 8 - 9

- Usage & Applications

- Used in linings for glass and steel furnaces, kiln furniture, and high-temperature industrial applications

- Water Absorption

- Negligible

- Chemical Composition

- Al2O3-SiO2 based

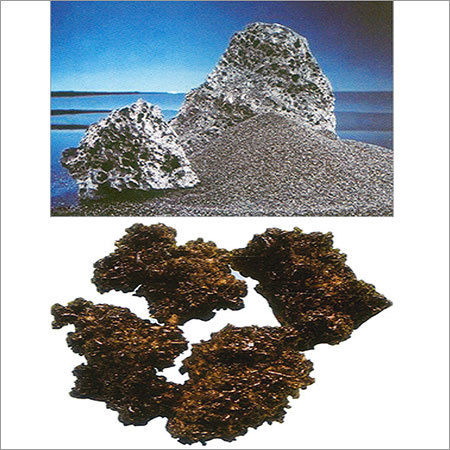

- Form

- Solid / Lumps / Granular

- Melting Point

- Approximately 1850C - 1900C

- Product Type

- Fused Mullite

- Types of Refractories

- Acidic refractory, synthetic mullite

- Shape

- Lump, granule, or specified shapes

- Porosity

- Low

- Dimensional Stability

- Excellent at elevated temperatures

- Strength

- High compressive and bending strength

- Specific Gravity

- 2.7 - 3.0

- Thermal Conductivity

- Low

- Color

- Off white to light brown

- Packaging

- 25kg bags, 1MT jumbo bags, or as required

- Loss on Ignition (LOI)

- <0.5%

- Resistance

- Excellent resistance to thermal shock and slag corrosion

- Particle Size

- Customizable as per requirements, generally 0-3mm, 3-5mm, or lumps

- Bulk Density

- 2.8 - 3.1 g/cm

- Thermal Expansion

- Very low thermal expansion coefficient

- Refractoriness Under Load (RUL)

- >1700C

About Fused Mullite

We are extensively reckoned as one of the well known importers, exporters and suppliers of widely appreciated Fused Mullite. Developed using excellent quality raw materials, these mullites are suitable for casting all type of alloys and metals. Our reputed vendors professionals process the entire assortment of chemicals in accordance with the international quality norms and standards. The offered Fused Mullite are given to the clients in variety of size fractions as per the requirements of our esteemed customers.

Features:

- High thermal stability

- Low reversible thermal expansion

- Resistance to slag attack at high temperatures

- Stable chemical composition

Process of Production :

Fused Mullite is produced by Bayer process alumina and high purity quartz sand while fusing in super-large electric arc furnace.

It has a high content of needle-like mullite crystals which confer high melting point, low reversible thermal expansion and excellent resistance to thermal shock, deformation under load, and chemical corrosion at high temperature.

Application :

- It is widely used as raw materials for high grade refractories, such as the lining bricks in glass kiln furnace and bricks used in hot wind furnace in steel industry.

- It's also used in Ceramic kiln and petrochemical industry and many other applications.

Technical Specification :

| Items | Unit | Index | Typical | |

| Chemical composition | AI2O3 | % | 70.00-77.00 | 73.90 |

| SiO2 | % | 22.00-29.00 | 24.06 | |

| Fe2O3 | % | 0.1 max (Fines 0.3% max) | 0.08 | |

| K2O+Na2O | % | 0.40 max | 0.16 | |

| CaO+MgO | % | 0.4% max | 0.08 | |

| Refractoriness | oC | 1850 | ||

| Bulk Density | g/cm3 | 3.00 min | 3.1 | |

| Glass phase Content | % | 5 max | ||

| 3AI2O3.2SiO2 Phase | % | 95 min | ||

Exceptional Thermal Shock Resistance

Fused Mullite stands out for its excellent resistance to thermal shock and slag corrosion, ensuring enhanced durability in demanding industrial processes. Its low thermal expansion coefficient makes it particularly suitable for kiln furniture, glass furnaces, and other high-temperature applications where rapid temperature changes are common.

Versatile and Customizable Particle Sizes

Available in tailor-made particle sizes, including 0-3mm, 3-5mm, and lumps, Fused Mullite adapts to specific requirements of diverse industries. This flexibility allows customers to select the most suitable grade for their intended use, whether for linings or intricate ceramic components.

Outstanding Physical and Chemical Properties

With high purity (>98%), Mohs hardness of 8-9, and refractoriness under load above 1700C, Fused Mullite delivers superior mechanical and chemical stability. Its low loss on ignition (<0.5%) and low thermal conductivity further enhance its performance in critical applications.

FAQs of Fused Mullite:

Q: How is Fused Mullite used in industrial applications?

A: Fused Mullite is primarily employed in high-temperature environments such as glass and steel furnace linings, kiln furniture, foundries, and the ceramics industry. Its thermal stability and resistance to chemical attack make it highly effective for these demanding applications.Q: What are the available forms and particle sizes of Fused Mullite?

A: The product is offered as solid lumps, granules, or in specified shapes. Typical particle sizes include 0-3mm, 3-5mm, or lump form, with the possibility of custom sizing to meet specific requirements.Q: When should Fused Mullite be preferred over other refractory materials?

A: Fused Mullite is preferred for applications that demand low thermal expansion, high resistance to thermal shock, superior slag corrosion resistance, and excellent dimensional stability at elevated temperatures.Q: Where can Fused Mullite be sourced and in what packaging?

A: Suppliers, exporters, and importers in India offer Fused Mullite, typically packaged in 25kg bags, 1MT jumbo bags, or customized packaging according to customer needs.Q: What is the process for customizing particle size and shape for Fused Mullite?

A: Customers can specify their requirements for particle size and shape when placing orders. The manufacturing process allows tailoring of these parameters to suit particular industrial needs, ensuring optimal performance in end-use applications.Q: What are the main benefits of using Fused Mullite in refractory applications?

A: Key advantages include high compressive and bending strength, low porosity, minimal water absorption, low thermal conductivity, and outstanding dimensional stability at high temperatures, resulting in longer service life and reduced maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Refractory Minerals Category

Brown Fused Alumina

Color : Brown

Dimensional Stability : Other, Excellent at high temperatures

Strength : High crushing strength, suitable for heavyduty industrial use

Application : Abrasives, refractory materials, blasting, grinding, surface preparation

Types of Refractories : Basic Refractory

Specific Gravity : 3.9 g/cm

Boron Carbide

Color : Black / Gray

Dimensional Stability : Other, Excellent

Strength : High mechanical strength

Application : Industrial abrasives, nuclear reactors, armor, nozzles, refractories

Types of Refractories : Other, Acidic Refractory

Specific Gravity : 2.52

Calcined Bauxite

Color : Brown, Grey, Reddish Brown

Dimensional Stability : Other, Stable at high temperature

Strength : High mechanical strength

Application : Refractories, Abrasives, Blast Furnaces, Steel, Cement, and Glass Industries

Types of Refractories : Other, High Alumina Refractory

Specific Gravity : 3.25 3.45

Crushed Ceramic Grains

Color : Beige to light brown

Dimensional Stability : Other, Excellent

Strength : High compressive strength

Application : Abrasive blasting, surface preparation, refractory filler, grinding and polishing

Types of Refractories : Other, Ceramic refractory grain

Specific Gravity : 2.6 2.8 g/cm

GST : 33AZHPS1057K1Z6

|

|

CERAMICS INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry